Battery Replacement of SLC 5/03, SLC 5/04, and SLC 5/05 Modular Processors

The SLC 5/03, SLC 5/04, and SLC 5/05 Modular Processors are integral components of Allen-Bradley's SLC 500 series PLCs, commonly used in industrial automation. The SLC 5/03 serves as an entry-level option, offering limited memory and I/O capacity. The SLC 5/04 provides increased resources suitable for medium-sized control systems, while the SLC 5/05 offers the highest capacity, catering to larger and more complex applications. Modular in design, these processors can be expanded with additional I/O modules and programmed using software like RSLogix 500.

Replace the Battery

Your SLC processor provides back-up power for RAM through a replaceable lithium battery. This battery provides back-up for approximately 2 years. The BATT LED indicator on the front of the processor alerts you when the battery voltage has fallen below a threshold level.

To replace the lithium battery, follow these steps:

⚠️ Note: Do not remove the processor from the SLC 500 chassis until all power is removed from the SLC 500 power supply. If you remove the power supply while power is applied, an electrical arc can occur. This could cause an explosion in hazardous location installations.

- Remove power from the SLC 500 power supply.

- Remove the processor from the chassis by pressing the retainer clips at both the top and bottom of the module and slide it out.

⚠️ Note: Do not expose the processor to surfaces or other areas that may typically hold an electrostatic charge. Electrostatic charges can alter or destroy memory.

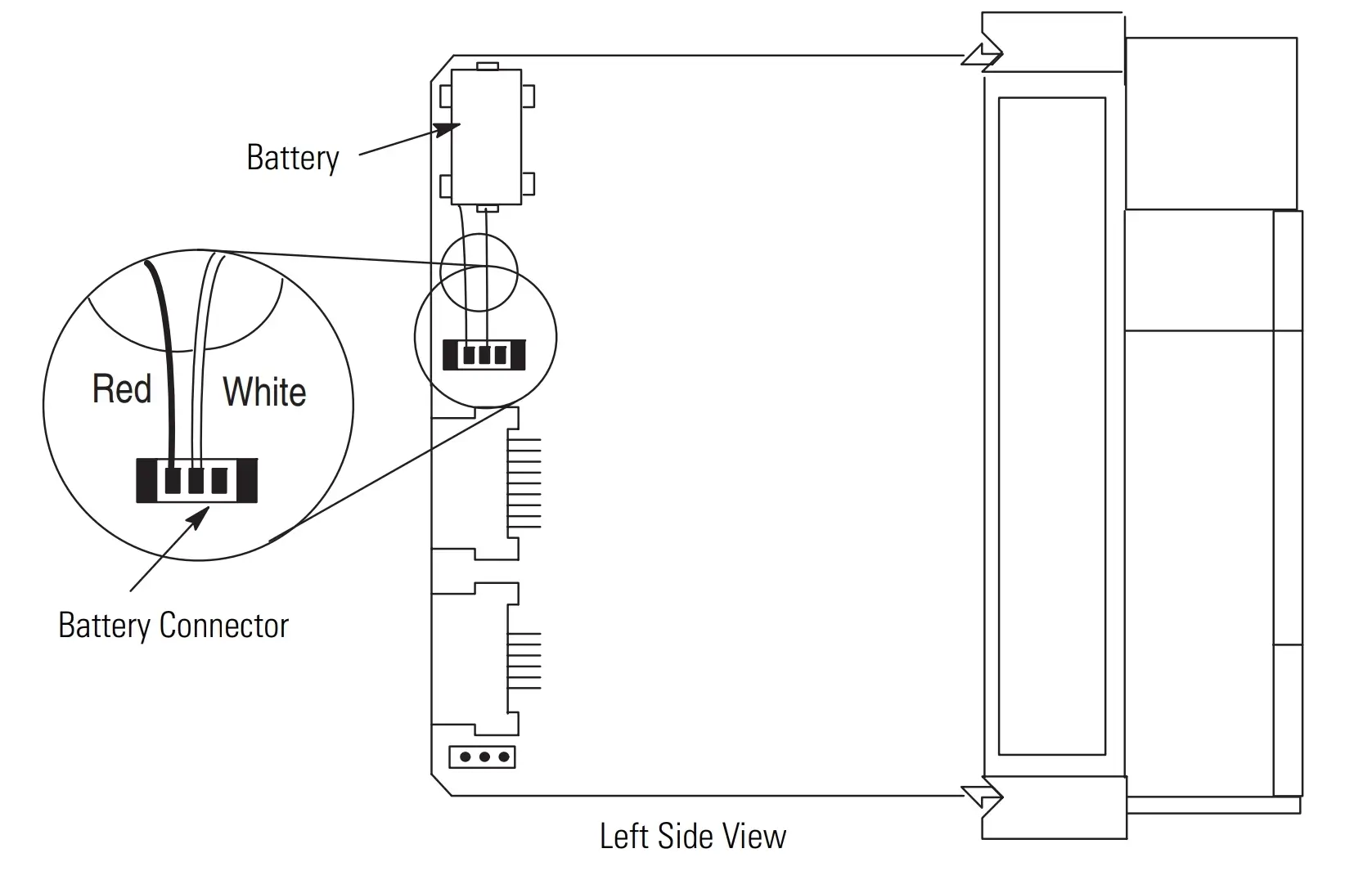

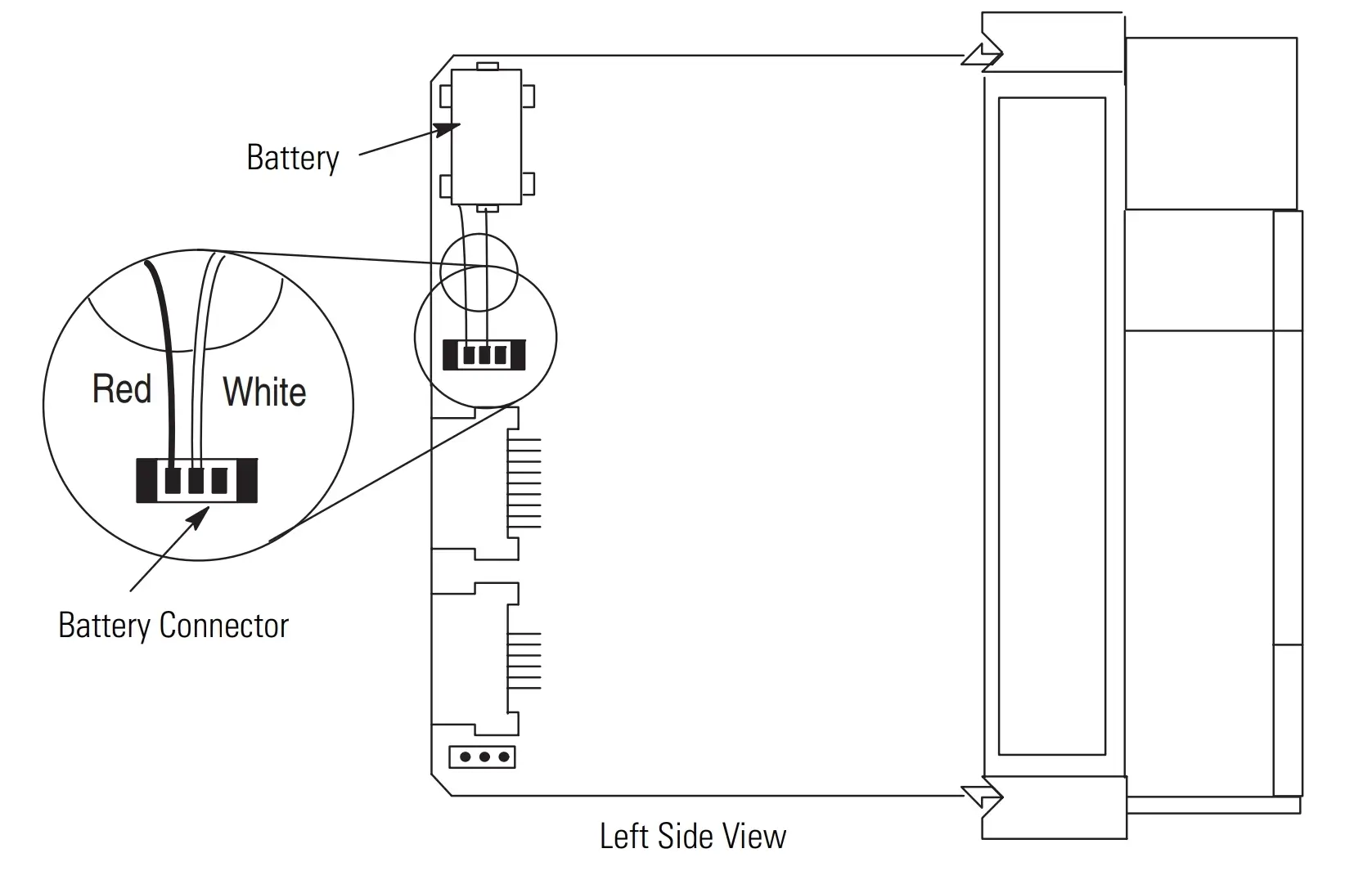

- Unplug the battery connector.

⚠️ Important: The SLC 5/03, 5/04, and 5/05 processors have a capacitor that provides at least 30 minutes of battery back-up while the battery is disconnected. Data in RAM is not lost if the battery is replaced within 30 minutes.

- Remove the battery from the retaining clips.

- Insert a new battery into the battery retaining clips.

- Plug the battery connector into the socket as shown above.

- Re-insert the module into the SLC 500 chassis.

- Restore power to the SLC 500 power supply.

- Close the processor door.

Remember to follow these steps carefully to ensure proper replacement of the lithium battery in your SLC processor.